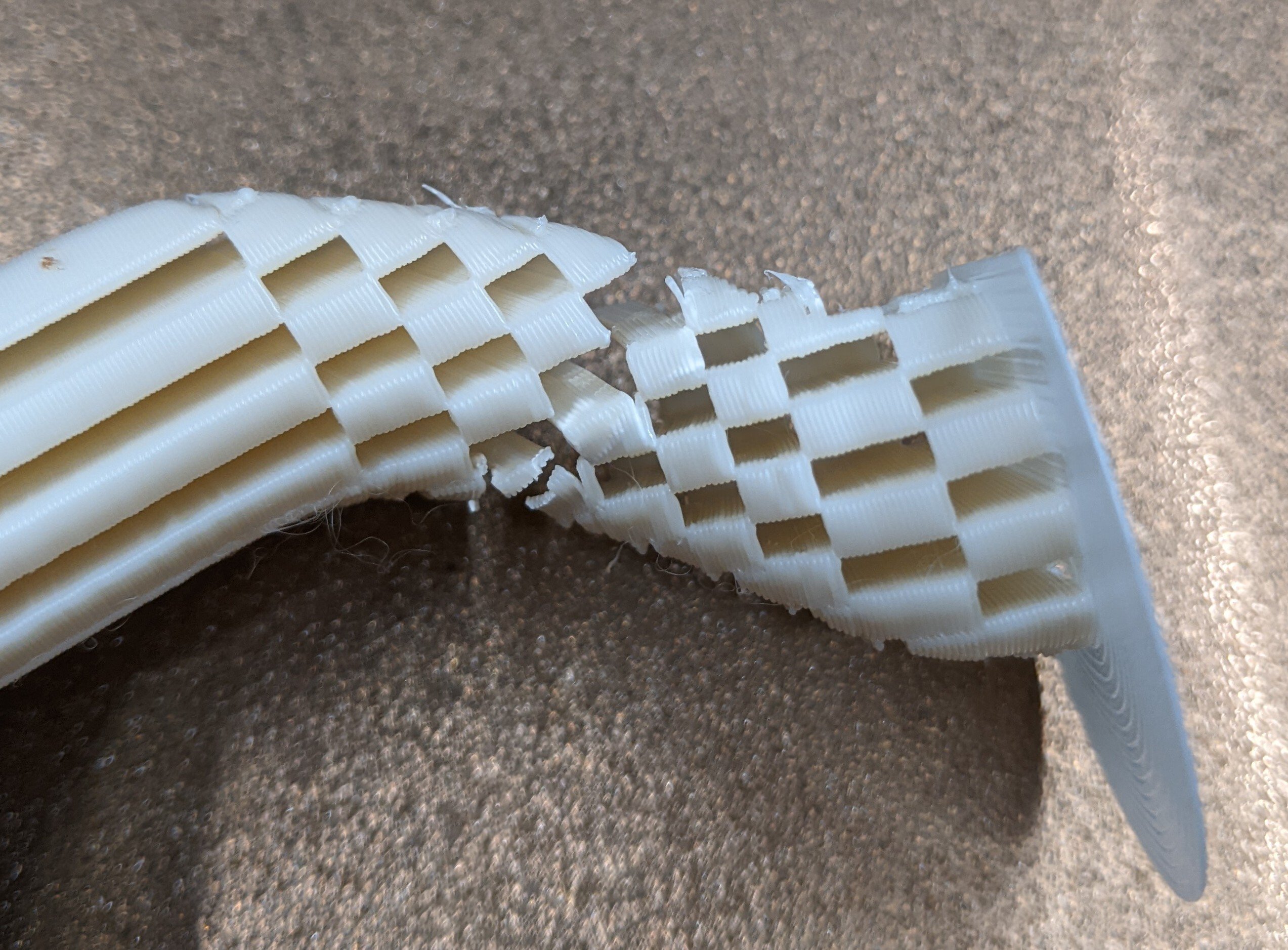

At least so far. The first go round had the nozzle crash into the tree support, resulting in a layer shift. The good news is that the print stayed very firmly stuck to the bed.

I’ve reset, lowered my extrusion multiplier a smidge, switched to a more traditional support pattern, and am going for it again. Wish me luck!

I made a sleeve of aluminum foil bubble insulation for mine. I taped it together with aluminum HVAC tape. It makes the enclosure heat up quicker, but I have to run the enclosure fan on longer prints to keep it from getting too hot.

This is basically what I’m planning on doing to make this look a bir nicer in the future. Do you change your bedfan speed via macro or do you only rely on your exhaust fan to regulate the temp?

I just use the exhaust fan for temperature control.