cross-posted from: https://lemmy.dbzer0.com/post/8959162

I had a rod that was threaded on one half and smooth on the other half. I needed the smooth half to be installed into brick.

method 1: chemical anchor

The normal way to do this (I think) would be to cut some grooves into the rod using an angle grinder, drill a hole that has a diameter that’s ~2mm bigger than the rod, and use chemical anchoring. But that stuff is pricey and only lasts ~1 year on the shelf. Thus cost ineffective for 1 use.

method 2: ad hoc chemical anchor substitute

Similar to the above, I wonder if general 2-component household epoxy would work as a substitute in the above method since people are more likely to have that on-hand. I suspect the issue is that it’s too thin and gravity would do its thing and the topmost area would not get filled with epoxy. Hence why I did not attempt it.

method 3: (What I did)

The rod measured at ø=8.8mm. I had no 9mm drill bit for masonry (and that would be too loose anyway). So I used a nominal 8mm masonry bit on a hammer drill. I’m not sure what the actual diameter of that resulting hole was, but it was too tight to push in the 8.8mm rod in by hand. So I tapped it in, dry (no oil or glues). It worked! It feels really solid. Feels like I got away with murder.

Questions

(method 2) Is there something could be mixed with common 2-component household epoxy to thicken it so it acts more like chemical anchor epoxy?

(method 3) Did I take bad risk with fracturing the brick? Is there perhaps a guide somewhere that safely maps brick hole diameter to metal rod diameter? Or is this something is never done and should never be done?

That depends wether you’re applying a pulling force on it or just a sideways force and how big of an issue it’s going to be if and when it comes loose. Temperature swings affect metal and brick differently so the hole might start crumbling around the rod after some years and it might come loose. It’ll definitely never be as tight as it is now.

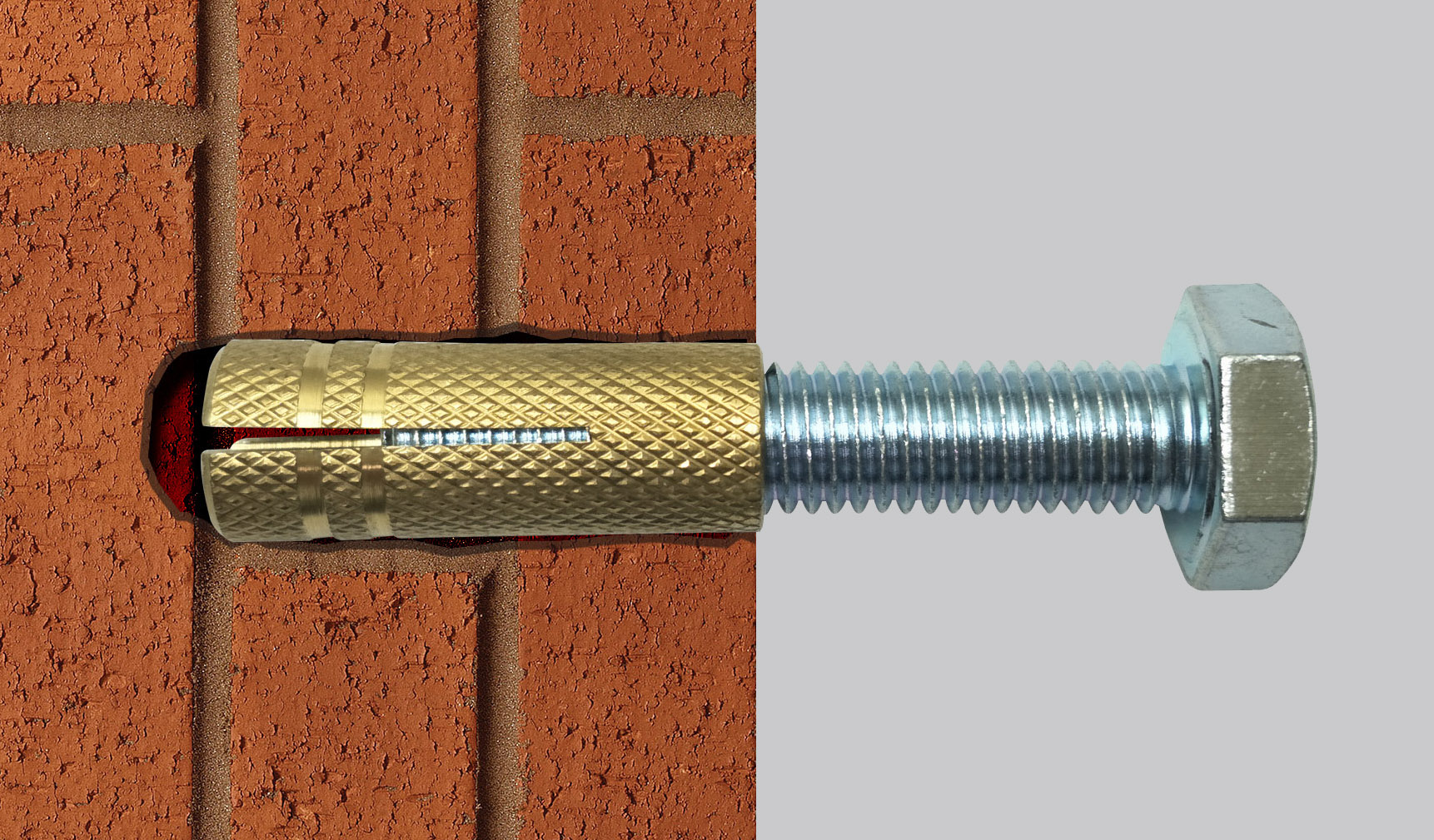

This might come a bit too late but why didn’t you just get threaded rod and use one of these instead?

I could not pull it out with my hands after tapping it in. But to be clear, there’s only a sheer force to deal with, and it’s light.

I cut a bicycle axle bolt in half, and embedded it in the brick so there is a bicycle sprocket on the wall. Then a chain wraps another sprocket, which turns a shaft that goes all the way though the wall to the other side, where it connects to a right-angle gearbox, which attaches to a water valve. It’s lightweight overall… just the weight of a sprocket, chain, and a small decorative wood thing out of wood to serve as a handle.

This might come a bit too late but why didn’t you just get threaded rod and use one of these instead?

I did not know anchors like that existed for machine bolts. That’s good to know! However, it would not have helped in this situation. The bicycle axle has non-standard threading (~9mm bolt with a thread pitch that’s 2 steps away from the norm). Since it had a special nut that interfaced to ball bearings, I could not bring in a standard bolt or threaded rod. And the threaded portion of the axle was short enough that no threads could have gone into the wall. I could have added threads to the bare portion, but my die set skips the ø=9mm size.

I was asking more for future reference – whether or not I should ever repeat this. And I think you answered that. Even if I get lucky in the future on getting a perfect fit at that moment, temp changes could blow it. I guess I’ll assume anchors (chemical and mechanical) are designed to handle the temp changes.

Mechanical anchors handle in my experience pretty much everything. I like the plastic ones from Fischer. And they make them for pretty much any application you could wish for.

I’ve had metal anchors in my walls that corroded over time. I’m not sure if corrosion causes expansion, but all those bricks split. That would be my only worry.

That’s good to know. I would hope a metal anchor to reshape when temp causes expansion. It’s a shame to hear it’s the brick that’s forced to expand. In my case it’s a solid metal rod, so it sounds like the metal is guaranteed to split the brick in a temp change.

It sounds like I have to pull out the shank, bore the hole to 10mm, and either use chemical anchor or fasten it using a sheet metal w/2 nuts.

deleted by creator