Just your ordinary average everyday Scottish bampot and circumbendibus relator of infantile jocundity

- 3.47K Posts

- 60 Comments

1·5 days ago

1·5 days agoExactly, but this is what gets classed as ‘actual factual news’ these days.

The very same story from another source:

Lead researcher and UTS Ph.D. candidate Michaela B. Smith investigated the impact of the most accurate, new-generation lunar dust simulants on human lung cells in the lab. She compared the effects to those of airborne particulate matter collected from a busy street in Sydney.

The study found that while the sharp, abrasive lunar dust can act as a physical irritant, it did not cause the severe cellular damage or inflammation seen from the urban Earth dust.

2·6 days ago

2·6 days agoThe cosmic vibrations oozing from the world wide web of ectoplasm are hinting that perhaps you may just not be overly enthused by the calibre of mystical and mysterious articles of unknown origin being posted to this community …mmmm?

OK…What about a crop circle then?.. Crop circles are relatively harmless, unless you are a stalk of grain that is, would a report on one of these brighten your day?

If so…How’s about two crop circles?

Yip, there have been two new crop circles reported in Wiltshire recently… Are crop circles any better?

If not, there are rumours that an Abominable Big Foot thingy has been sighted around the Midlands, and don’t forget we always have Nessie, come on who doesn’t like to hear a ripping good yarn about The Beastie? 🙄😁

2·6 days ago

2·6 days agoWhat about werewolves then?

The Daily Star is carrying an article claiming that there is an eight foot tall werewolf lurking in some bushes near Bridlington!

Quote:

The eerie image shows what appears to be an 8ft-tall shadowy figure emerging from a ridge with a strange glow around its head.

It looks like any other common or garden everyday average Joe strolling past a gap in the bushes to me, but hey, who am I to decide what makes a fantastical tale newsworthy? Anyway, what more could you possibly ask for in a news headline?.. Expert opinion, ominous warnings, werewolves and bushes… Boo! 😄😁

https://www.dailystar.co.uk/news/weird-news/spine-chilling-photo-werewolf-spotted-35420732

3·10 days ago

3·10 days agodeleted by creator

1·12 days ago

1·12 days agoIt is merely a theory, the only known definite fact is the fact that nobody knows!

1·16 days ago

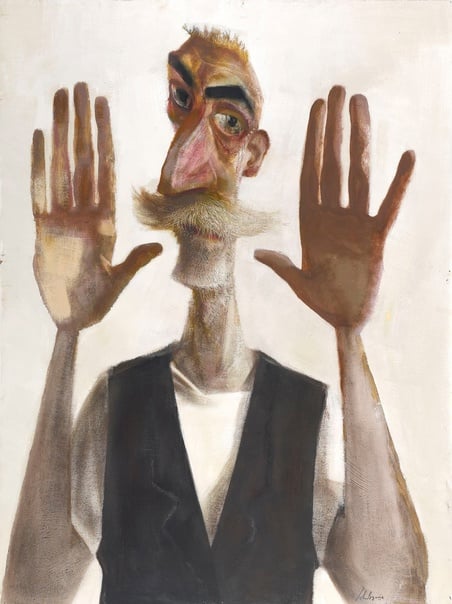

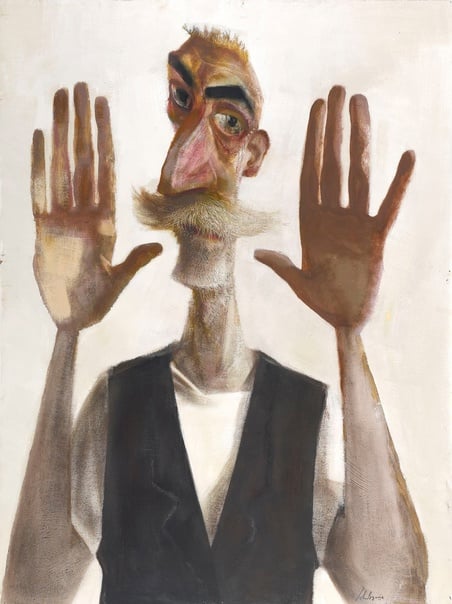

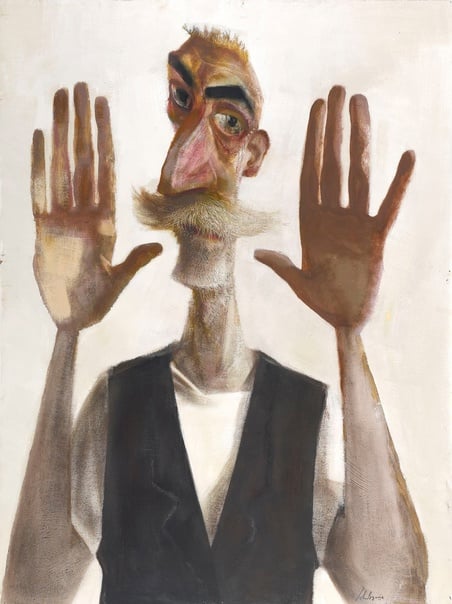

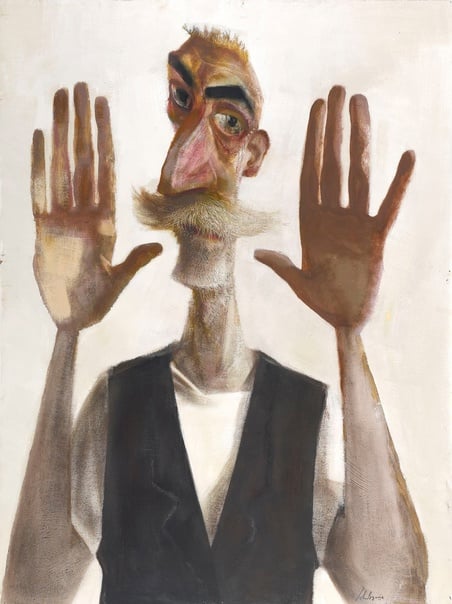

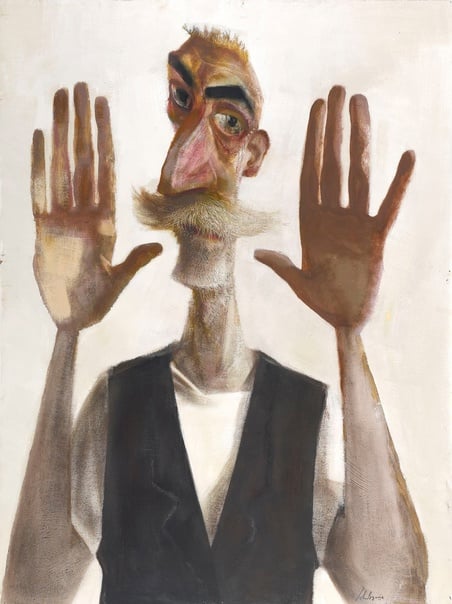

1·16 days agoIs yer man there not a fifth dan blackbelt in freemasonry? Are you in your cool season down there just now? Stay safe young man.

1·19 days ago

1·19 days agoIs it not a WTB (Wind Turbine Base)?

I seen a peanut stand, heard a rubber band

I seen a needle that winked its eye

But I be done seen about everything

When I see a turbine base fly

But who knows, I suppose this all depends on the size of the turbine that gets bolted on to it, stranger things have happened at sea!

1·23 days ago

1·23 days agoWhat is your problem? I did nothing of the sort.

Obviously you have not even read the post - That is the title of the article.

For your information, how posting on here works:

1: Copy and paste article URL

2: The Article title then comes up underneath the URL

3: If you wish, copy and paste the post body

4: Choose your community

5: Press the share arrow

Goodbye

1·24 days ago

1·24 days agoI did not write the article, plus I do not think posting the truth about the deadly outcomes of silica dust exposure is promoting clickbait, I call this relaying fact.

This page covers occupational diseases, especially silica exposure…The Danger Dust campaign started over 20 years ago and ran on Facebook,Twitter, Reddit, LinkedIn then here…The whole idea of those pages was to raise awareness on the subject of dangerous dusts, fumes, fibres and chemicals, not to gain followers or likes for posts.

The guys have been campaigning in parliament for years, now there are very few of them left, those who have already boarded the Astral Plane expired from exposure to dust…Do not worry though, there are many more dusty sick working their way up the ladder to take our places on the campaign trail.

Tell them they got sick from clickbait!

Nobody forced you to read the article.

11·24 days ago

11·24 days agoSorry you feel the way you do about the headline, but unfortunately that is the name the village is now known by, it has been so called for very many years … Dust Kills!

This is from 2017, I can go further back if you like?

Radha counts on her fingers the number of people in her family afflicted by silicosis. Her husband, his two brothers, her oldest daughter, all of them have died. She says she might be the next victim of silicosis.

Radha and Hira are from Budhpura, a “village of widows” in Bundi, situated in the middle of huge sandstone mines. The district of Bundi and the neighbouring districts of Bhilwara and Kota are hubs for sandstone export to Europe.

https://www.aljazeera.com/features/2017/11/12/curse-of-silicosis-haunts-village-of-widows-in-india/

1·24 days ago

1·24 days agoBut can these life forms be exploited by the corporates and turned into Bitcoin?.. This is the big question!

4·25 days ago

4·25 days agoExactly!..But what worries me most is that AI generated tabloid journalists are now lifting content from social media platforms and publishing this as actual factual news!

Jimmy Jango stated on X that he contracted the rare condition known as Ectoplasmic Frankensteinosis by sniffing the rear ends of his chocolate dinosaurs.

1·26 days ago

1·26 days agoI think this news aggregator (just like nearly all of them these days) uses AI to create articles.

Below is a link to one of the papers the article was lifted from -

Global, regional, and national burden of acute leukemia and its risk factors from 1990 to 2021 and predictions to 2040: findings from the global burden of disease study 2021

https://biomedical-engineering-online.biomedcentral.com/articles/10.1186/s12938-025-01403-7

2·26 days ago

2·26 days agoG’day, Jings and jingszo Indeed Mr Sabatron. I hope all is good down there in the underworld … Heeeeucht!

2·1 month ago

2·1 month agoSo you are a time travelling tourist from the future? Crikey!

1·1 month ago

1·1 month agoExactly, it’s not a right , it is the law… And not just simply because it’s illegal to piss and shit in the street.

3. Toilets and washing facilities

Employers have to provide facilities suitable for any worker, including those with disabilities, which includes:

https://www.hse.gov.uk/simple-health-safety/workplace-facilities/health-safety.htm

2·1 month ago

2·1 month agoExactly, define a reliable source?

deleted by creator

deleted by creator