Had an old Wahl just die after probably a good 20+ years, kind of looks like the cable is frayed and splitting where it connects to the trimmer. Did a quick check online and the new products don’t even look remotely similar.

Just using it for normal hair cuts at home, any recommendations?

Edit: Preferably on the budget side.

If the cable is the only thing, you can likely open it up and replace it.

Why not fix the cable? Should be cheap and well, youre talking about BifL, well heres your chance to keep an old item running… for life.

People often lament that things these days don’t last as long as they used to, but they forget that our grandparents were constantly mending clothing, repairing electronics, etc.

I did this with a similarly old and heavily used Philips trimmer and it has lasted a good few years since. The Wahl ones are handy enough to take apart if memory serves so if you can I would also recommend going this route.

If you can get the casing off and post pics I’d be happy to offer advice if it’s not something you’re comfortable with.

Post a pic of it? It might be fixable

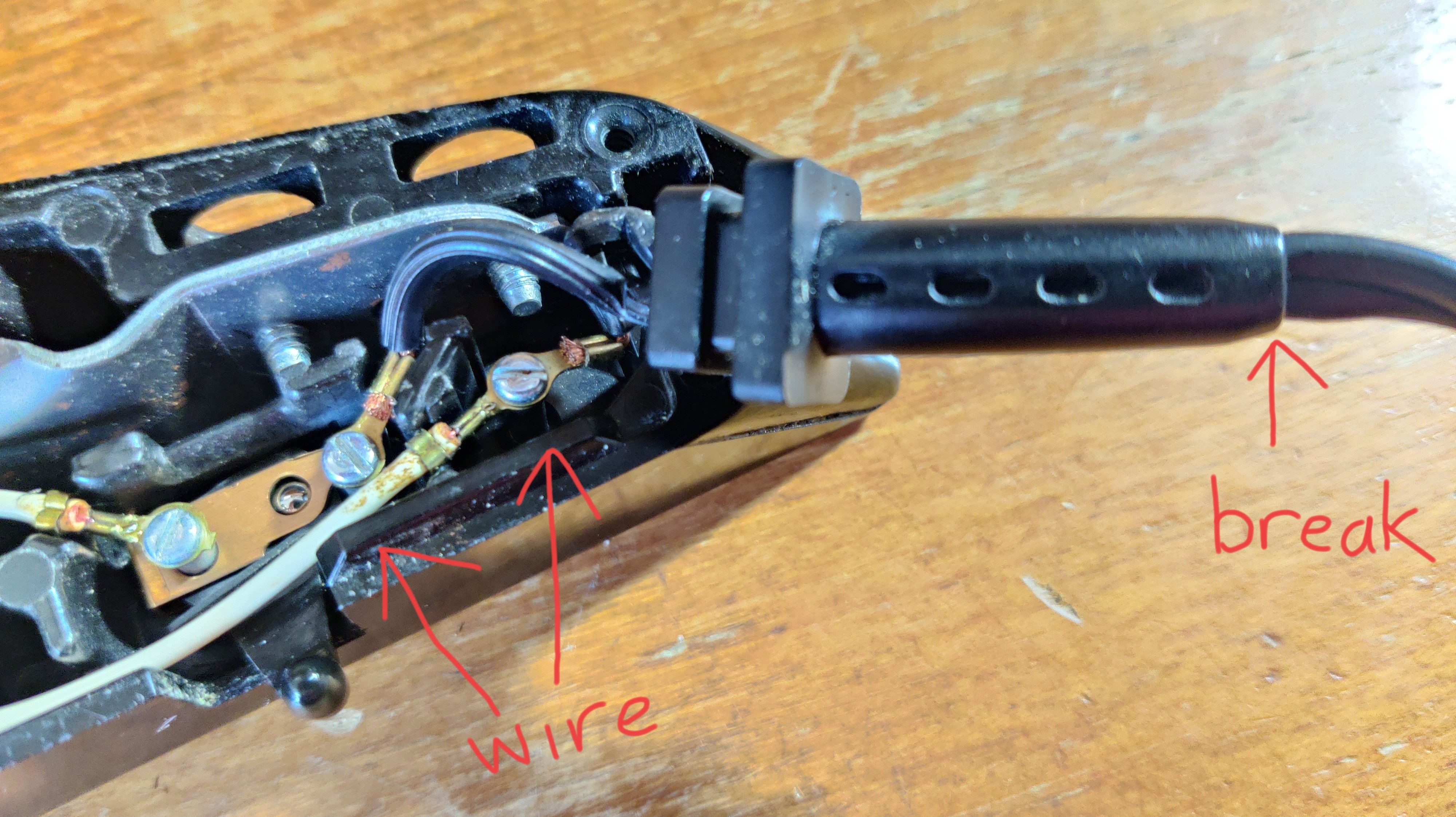

First time uploading a picture here so not sure if it worked, but how does it look? I honestly have no idea how to fix it.

Inside the trimmer, it really does look more simple when you open it up. Let’s say I can just cut the wire down a bit with scissors and then strip a bit of the cable plastic. Then the points I’m uncertain on would be:

-

The rubbery fitting that surrounds the wires and secures it to the main housing. Doesn’t feel like there would be any way to yank out existing cable and thread through the unbroken part.

-

Little gold-ish pieces that pinch the wire and connect it to the screws. Look somewhat difficult to pry open.

I am located in the US but not sure which prong is which since the cable is quite twisty and the broken part is on the trimmer side.

Thanks everyone, looks like it works for now!

-

Unscrew one of the wire terminals. Wrap a piece of tape around it so you know which wire is which. Unscrew the other wire. I think you should be able to pull the wire through that stress relief and then cut it off on what would be the inside instead of cutting it off outside and trying to thread it through the molded rubber. It might be stiff but you can try putting a little soap on it to lube it up. You may or may not have to split the jacket down the middle between the 2 wires depending how the relief is molded.

-

If you’re soldering, just cut the wire at the terminal ring and solder the wire right to it. You can also get new crimp on terminal rings. Take an old one to the store to match it up to get the right size.

Disclaimer: not electrician, just a DIYer that doesn’t like to spend money

Another idea on point 1 for pulling the wire through the stress relief would be to heat it up a little bit (with hot water or something) to make it more pliable.

Ah, yes, if it has some rubber cement type goop in there, a hair dryer will work as well. Good call.

-

-

Pic looks good. Probably the best option is to trim that cord a little past that break, remove the broken section, and insert the trimmed cord and reattach it to the trimmer. This will probably require soldering, and will definitely require opening the case. A picture of the trimmer with any visible screws shown will help to determine how feasible this is. You will require some solder, a soldering iron, and some flux. If you haven’t done soldering before, this could be the most forgiving project to learn it on. Electrical soldering is pretty easy, electronics are fairly precise.

The picture came thru great, and I think that’s fixable. A couple starting questions are: can the trimmer be easily opened up/ are there obvious screws keeping the housing together? Is the plug polarized? if you’re in the US this means one of the prongs of the plug is larger than the other.

Edit: i’m gonna try and find a video tutorial or something on this as I think explaining via forum post might be kinda cumbersome, but I am down to try and help you through it.

Oster Fast Feed is not a “budget” pick, but then again, few BIFL options are.

Edit: 76023-510 is the corded model.

This, plus the purple Andis magnetic blade guards. BIFL kit for the homegamer.

I recommend the repair option first, but I also have these clippers and they are really nice.

I looked, and I couldn’t find any. It’s all Chinese brands now with no repairability. I bought a Phillips because it had a lot of features and it was cheap. When the battery dies, I can still use it corded. I do need to find some grease though so that the plastic motor nub doesn’t grind away too quick.

Not Phillips norelco

If you have a Harbor Freight nearby grab this https://www.harborfreight.com/150-piece-terminal-and-connector-set-67683.html and a pair of crimpers for the inside electrical connections. A pair of wire strippers and you’ll be on your way.

K, my hair is crimped and full of these plastic beads, but I still need a haircut. Should I use the clippy bit of the wire strippers?

That’s a clever idea.

Probably the best option. If it’s last 20 years, it can probably do another 20. And anything you find currently on the market will struggle to beat that.

Yeah, I just checked their site and most of the stuff looks like it would break if you looked at it wrong.

I think I have some iteration of this model https://wahlusa.com/shop/clip-n-trim-corded-hair-clipper-with-built-in-trimmer-79900-1501p though, and it’s held up pretty well (plus they have replacement blades on their site for it).

Not sure if it’s buy it for life, but it’s lasted 5 years so far for me.

Wahl got bought out years ago. Super cheap and shitty product all around. Chipped clipper blades, cheap plastic especially internals, dull loud blades. Avoid. Forgot: Philips is the same. Avoid both.